Filter/Clone® Dust Control System was developed by Joe Tipton, Inc. in April 1979.

The first Filter/Clone® cyclonic dust collector was introduced in that year in the form of a 600 cfm total collection system used primarily on small air–track percussion rock drills. That unit was the result of 15 years of experience of the founder, Joe Tipton, in research, design and development of elementary dust collectors for the mining and construction industries.

Utilizing the patented and proven cyclone separation principle with barrier filtration in the vortex of the cyclone, the initial design has evolved into a complete product line of collectors with capacity to 12,000 cfm.

The result is a highly–efficient design which utilizes all of the necessary relationships among volume of air, filter area, horsepower requirements, hose size, pickup and conveyance criteria, and other factors.

In addition, for drilling conditions where chip collection is not required and where space requirements dictate, a line of non–cyclonic baffle type collectors has been developed.

Size 3SB dust collector on Ingersoll–Rand drill

Size 3SB Filter/Clone® dust collector on Ingersoll–Rand T4 truck mounted drill. The hydraulic controlled total collection pickup post is shown with the tower raised for drilling.

Size 3IR total collection pickup pot

Close–up of Size 3IR Filter/Clone® total collection pickup pot on Ingersoll-Rand drill. The dust collector is removing all material exiting the drill hole.

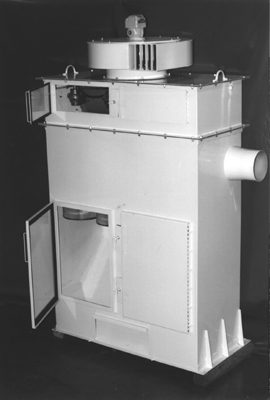

Size 3600 dust collector with filter and valve access doors open

Size 3600 Filter/Clone® dust collector with the filter and valve access doors open.

Size 4500 dust collector has nominal suction capacity of 4500 cfm

Size 4500 Filter/Clone® dust collector has a nominal suction capacity of 4500 cfm and uses a 10" ID suction hose.

Joe Tipton, Inc. is in a unique position to meet the dust control needs of virtually any rock or rotary drill on the market.

The company brochure and other materials on the Download page provide greater details.

Contact Joe Tipton, Inc. or a Dealer in your area to add a Filter/Clone® Dust Collector to your drill(s).